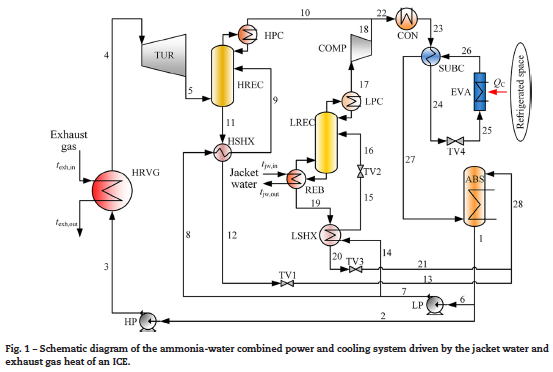

An ammonia-water combined power and cooling system is proposed and investigated in this work, in which the waste heat contained in the jacket water and exhaust gas of an internal combustion engine can be recovered efficiently to generate power and cooling energy simultaneously. The proposed system was simulated, and its thermodynamic performance in the base case was calculated based on waste heat data from an actual gas engine with a rated power output of 300 kW. The equivalent heat-to-power efficiency of the combined system is 19.76%, and the total equivalent power output is as high as 92.86 kW. The exergy efficiency of the combined system reaches 33.69%. The effects of the turbine inlet pressure, generation pressure in the reboiler, exhaust gas temperature and cooling water temperature were studied to provide guidance for the system design. The results of an economic analysis indicate that the proposed system has good economic benefit.

An ammonia-water combined power and cooling system was proposed in this study. The proposed system is driven by the jacket water and exhaust gas heat of an internal combustion engine simultaneously. The thermodynamic performance of the new system was calculated and analyzed. The cogeneration system is a combination of a power generation subcycle, an absorption refrigeration subcycle and an absorption compression refrigeration subcycle. The exhaust gas of the ICE is used to generate superheated ammonia-water vapor in the power generation subcycle. The heat and ammonia contained in the turbine exhaust vapor is utilized in the rectifier of the absorption subsystem. The jacket water waste heat is recovered and supplied to drive the absorption-compression subcycle. In the base case, the equivalent heat-to-power efficiency of the CPC system is 19.76%, and the total equivalent power output is as high as 92.86 kW. Based on the second law of thermodynamics, the exergy efficiency of CPC system is 33.69%. Exergy analysis gives the guidance for further system optimization.

The effects of four important parameters on the performance of CPC system were investigated: the turbine inlet pressure, the generation pressure in REB, the exhaust gas temperature of ICE and the cooling water temperature. The most applicable turbine inlet pressure is approximately 100 bar in the base-case boundary conditions, considering both the thermodynamic performance and economy. There exists a best possible generation pressure in REB, which is 5.9 bar when pTUR, in = 100 bar, texh,i = 500 °C and tCW = 30 °C. In addition, a higher exhaust gas temperature and lower cooling water temperature are found to be beneficial to the system performance.

The economic benefit of the combined power and cooling system was evaluated using the total capital investment, total annual cost and the dynamic payback period. The total capital investment of the proposed system is 1,094,090 RMB. The total annual cost is 166,124 RMB each year, with the annual capital cost accounting for the majority of the cost. Considering the time value of the capital, the payback period of the investment is 2.84 years, i.e., the investment has great economic benefit. An analysis of the economic sensitivity indicates that the cold price is the main factor that determines the economic benefit of the proposed system.

This study provides an efficient approach to utilize the waste heat of internal combustion engines for power and cooling cogeneration more efficiently. According to an economic analysis, the designed cogeneration system is profitable and applicable in China.