Zhundong coal from the Zhundong coalfield in in Xinjiang, China, is charactered by high content of Na. Na-related slagging of Zhundong coal is unclear. The aim of this study is to determine the influence of Na-based materials on the slagging characteristics of the coal. The raw coal was prepared by first removing Na by chemical extraction and subsequently impregnating it with the Na-based materials, such as NaCl, Na2SO4 and NaAc. Laboratory slagging experiments in a muffle furnace were conducted using the mixtures of prepared Zhundong coal and quartz sand. It was found that the Na-based materials affected the slagging behavior of the coal in the order NaAc/Na2SO4 > NaCl. For the mixtures with the NaCl additive, fusion was most noticeable at 900℃. However, for the mixtures soaked with Na2SO4 and NaAc, a monotonically increasing relationship was indicated between the degree of slagging and the temperature. Adding the Na-based materials to the coal resulted in increased Na content in the residual ash, especially in the instances with Na2SO4 and NaAc additives. The formation of silicates, which were ascribed to the reactions between the Na-based materials and the SiO2, was the primary cause of slagging. Various mineral elements, especially Fe, were captured by Na2O, derived from the decomposition of Na2SO4 or the combustion of NaAc, to exist in the form of a low-melting temperature eutectic. Additionally, the presence of Fe, Ca, K, and Mg in the ash aggravated slagging under the influence of Na2O.

Conclusions

The slagging behavior of Zhundong coal with the addition of NaCl, Na2SO4 and NaAc was studied in a muffle furnace at temperatures of 800℃, 900℃, and 1000℃, respectively. The mechanism of slagging caused by the Na-based materials in the Zhundong coal was investigated by a series of analyses. The main conclusions are as follows:

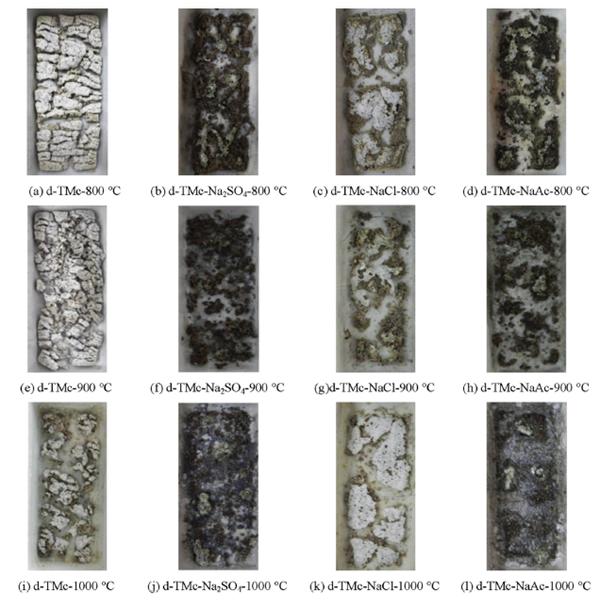

(1) Na-based materials brought about apparent slagging. The slagging degree varied according to the various Na-based materials, following the order of NaAc/Na2SO4 > NaCl. Additionally, with the separate addition of NaCl, Na2SO4 and NaAc, the ash colors were black-brown, brown, and sandy beige, respectively.

(2) NaCl reacted directly with silica to form low melting-point silicates. The formation of silicates was limited by the lack of hydrogen in the experimental conditions, restricting the slagging. The fusion was most obvious at 900℃.

(3) In addition, silicates were formed by the direct reaction between Na2SO4 and silica. The Na2SO4 decomposed into Na2O. The Na2O reacted with SiO2 to form silicates and combined with other mineral elements to form eutectics, leading to slagging. Additionally, the molten state of the Na2SO4 accelerated the occurrence of slagging. A monotonically increasing relationship was indicated between the degree of slagging and the temperature of the sample with Na2SO4.

(4) For the samples soaked with NaAc, the primary source of slagging was the Na2O derived from the combustion of NaAc. The Na2O showed a great attractive force to other mineral elements. The sodium iron oxides were proven to play an important role in slagging.

The results have been published on Journal of the Energy Institute 90 (2017) 914-922.

Fig.1. Appearance of residual ash at temperatures of 800℃(a-d), 900℃(e-h), and 1000℃(i-l), respectively.