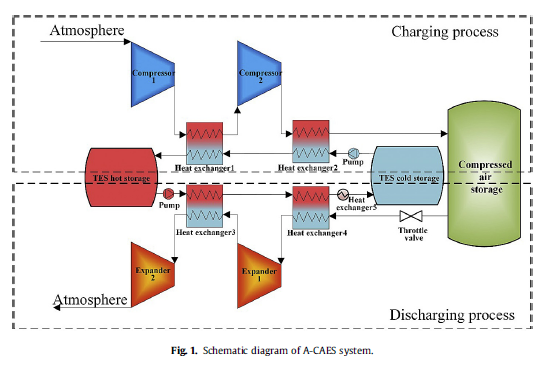

The compressed air storage connects charging and discharging process and plays a significant role on performance of Adiabatic Compressed Air Energy Storage (A-CAES) system. In this paper, a thermodynamic model of A-CAES system was developed in Matlab Simulink software, and a dynamic compressed air storage model was applied in the simulation, revealing the influence of time-varying temperature and pressure of air on performance indicators, e.g., roundtrip efficiency and energy density. The analysis results can be used as an explanation of the contradicting conclusions on system efficiency from other articles, as well as a reference in the design and operation of an A-CAES plant.

There exists an optimal after-throttle-valve pressure when applying energy density as objective function with constant expander inlet pressure. A relatively higher heat transfer coefficient between atmosphere and air in storage tank results in more stored air in charging process and more released air in discharging process, which are of great benefit for A-CAES system in terms of energy density. The dynamic performance characteristic of compressed air storage can affect design capacity of first heat exchanger of expansion train and moreover, reduce roundtrip efficiency and energy density of A-CAES system.

To study the effects of compressed air storage on performance of A-CAES under different working conditions, A-CAES system models were developed based on static and dynamic processes of air reservoir. From the results of the analysis, the following conclusions can be made:

(1) There exists an optimal after-throttle-valve pressure when applying maximum energy density as objective function with constant expander inlet pressure. It is a tradeoff between energy density and roundtrip efficiency, thus taking an appropriate value of after-throttle-valve pressure is of significance in designing an A-CAES system.

(2) The influence of different parameters on the performance of A-CAES system was evaluated by a parametric analysis. The fewer number of compression stages is, the greater system efficiency is when air storage pressure is fixed, and the optimal number of expansion stages equals to the number of compression stages. The air storage pressure shows no significant effects on roundtrip efficiency, but has a great influence on energy density. Energy density and roundtrip efficiency both gets lower in varying degrees when considering the dynamic characteristics of compressed air storage.

(3) A greater heat transfer coefficient between the air in reservoir and environment can result in more stored and released air in charging and discharging processes, and hence improve energy density, e.g., energy density increases by 35% when the heat transfer coefficient is from 10 to 100 W/m2/K. In addition, relatively smaller air temperature variation in a whole cycle is advantageous for the system with greater heat transfer coefficient. Therefore it is preferred to design a compressed air storage with higher heat transfer coefficient.

(4) The temperatures of the air in reservoir and after throttle can become extremely low when the heat transfer coefficient is small or discharging duration is short. When the heat transfer coefficient is high, the after-throttle-valve temperatures decrease first and then increase, causing a peak value for heat transfer rate of first heat exchanger of expansion train, which has to be taken into consideration when designing A-CAES heat exchangers for having enough heat exchange capacity.