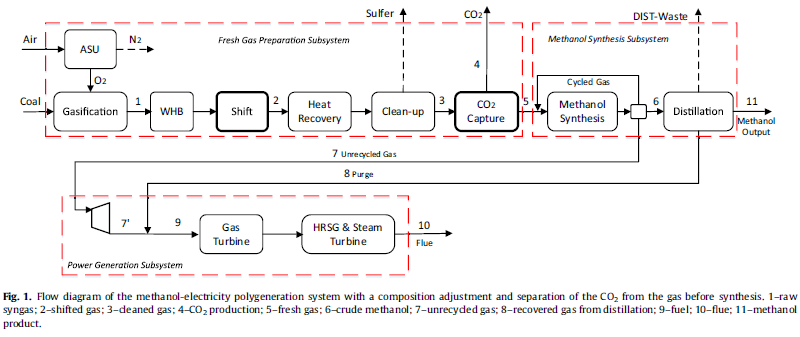

Polygeneration is identified as an effective way to overcome the challenges of energy efficient utilization and CO2 emission reduction. This paper analyzes the energy saving mechanism and carbon reduction laws of decarbonized polygeneration systems, and discusses the compatibility of CO2 capture for different integral schemes. Based on the novel method of chemical exergy balance, two typical methanol-power polygeneration systems with CO2 recovery are analyzed in detail, and integral factors that indicate the level of energy cascade utilization and the compatibility with CO2 capture are proposed. Both polygeneration systems show large performance improvements compared to the single production systems, but the advantages of scheme (b), removing the composition adjustment and capturing CO2 from unrecycled gas after synthesis, are more prominent. This scheme has an excellent compatibility with CO2 recovery, and it shows a fairly optimal performance in the full working field. Further, according to the analysis of the integral factors, a higher CO2 recovery ratio is recommended for scheme (b), while a lower one is recommended when scheme (a) is employed.

Fuel conversion is accompanied by the enrichment of COx, and a polygeneration system has the potential to capture CO2 with a low energy penalty. This paper analyzes the energy saving performance of two typical methanol-power polygeneration systems with CO2 recovery. It shows that Scheme (b), the integral scheme of removing the composition adjustment and capturing CO2 from unrecycled gas after synthesis, has better performance and combines CO2 capture in a more compatible way. Compared to the polygeneration system without CO2 capture, not only does ESR not decrease apparently, but it yields a fairly optimal performance in the field. Further, by dividing exergy into physical exergy and chemical exergy, this paper proposes a novel exergy analysis method. This method provides the ability to omit the physical processes in a complex system and simplify the system into one with only chemical processes, which more easily reveals the mechanism of chemical energy cascade utilization. According to the chemical exergy balance analysis, integral factors that indicated the system integral level are proposed. The performance improvements of polygeneration systems are attributed to three aspects: profit from chemical energy cascade utilization, profit from energy penalty reduction of CO2 capture and the effects of related physical processes. From this new perspective, this paper reveals the energy saving mechanism of polygeneration and proposes the integration principles of CO2 recovery to provide guidance for actual production. First, for different integral schemes, the profits from chemical energy cascade utilization are very similar when chemical production is required, and the difference in integral level is mainly due to benefits from the penalty reduction of CO2 recovery. As a result, those schemes with greater potential to obtain a higher CO2 concentration should have a higher priority. Second, a higher demand of CRR (>90%) is recommended for Scheme (b), since the advantage of CO2 separation in this scheme is prominent when a higher CRR is demanded. If a higher chemical production that exceeds the production capacity of Scheme (b) is required, Scheme (a) should be employed. Combined with the analysis of integral factors, the compatibility between chemical energy cascade utilization and CO2 capture in Scheme (a) has been proven stronger at a lower CRR (<66%).