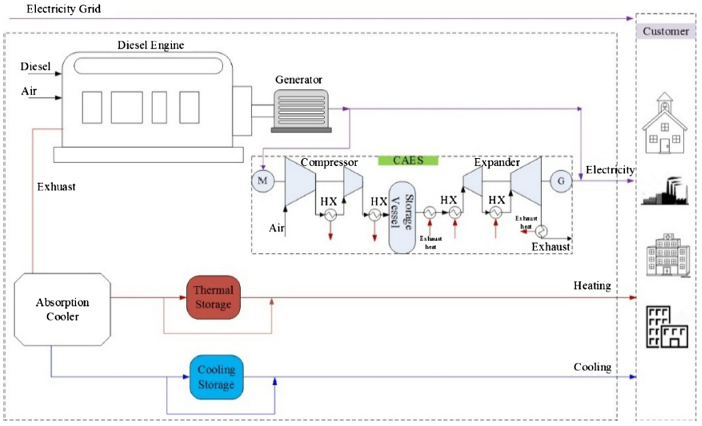

Due to its relatively high efficiency, Distributed Generation (DG) is widely used to supply energy sources (generally power, heating and cooling) for on-site needs. This, however, presents a challenge to deal with an abrupt increase of electricity demand. To satisfy 100% of electricity demand with a high level dynamic performance energy storage is one of the most promising options for the DG system. In this study a hybrid DG system integrated with Compressed Air Energy Storage (CAES) and Thermal Energy Storage (TES) is proposed. Coupled with energy storage the DG system can perform a ‘peak shaving’ function and maintain the power output requirement properly, resulting in a lower core engine power rating and better process efficiency. To carry out technical evaluation the process flow chart is created and process models are developed. The results of simulation are also validated by IET’s CAES experimental data. The results reveal that the hybrid system’s exergy efficiency is 41.5%, and the primary fuel saving ratio is 23.13%. The CAES expander system is operated in a sliding pressure mode, satisfying various load profiles while its exergy efficiency for one day cycle is 64.7%. Compared with conventional DG system, within the hybrid system the core engine size can be downgraded by 35.3%, the fuel saving ratio is 11.06%.

A MW-scale CAES demonstration system is constructed and measured by IET, which can be integrated into an on-site or near-site distributed generation system. Especially, the expander system can be operated in a sliding pressure mode, which is more suitable for the unstable power requirement of DG system. A design method for the DG integrated with energy storage is developed and a case study is carried out based on a school’s energy consumption profile. Storage tank and expander models developed are also validated by the IET’s CAES platform. Based on the process modelling, simulation and experimental analysis of the studied hybrid DG-CAES system and conventional DG system, the following conclusions can be drawn.

(1) When the energy storage system was introduced, the power rating of the core engine of the DE system can be downgraded by 35.3% and the DE system is operated stably and efficiently. The electrical and exergy efficiencies of hybrid DE-CAES system are 43.8% and 41.5%, respectively, 6.3% and 6.2% higher than that of conventional DE system without energy storage.

(2) The hybrid DE-CAES system reduces fuel consumption by 14.45% compared to a conventional DE system at ‘power only’ mode. If the hybrid DE-CAES system is operated at a tri-generation mode the fuel saving ratio of 11.06% is achievable. Compared with a system to supply electricity, heating and cooling separately, the primary fuel saving ratio is 23.13% for the hybrid DE-CAES system.

(3) The hybrid DE-CAES system demonstrates a good dynamic performance since its power output can be varied over a wide range by adjusting the inlet pressure of the CAES expander system (sliding pressure mode). The CAES exergy efficiency for one day cycle is as high as 64.7%.

(4) Taking the fuel saving expense as an income of the energy storage system, the ROI of the energy storage installation is about 8.9 years which can be much shorter considering the benefits of core engine size reduction and CO2 emission abatement.

Fig. 1. A hybrid DG with energy storage system.