To seek an appropriate additive for the preparation of erythritol-based composites, the evaluation and comparison of composites with the addition of EG (expanded graphite) and CNTs (carbon nanotubes) have been conducted in this paper. Composites with additive mass ratios of 1wt%, 3wt%, 5wt% and 7wt% were prepared by melting dispersion. The thermophysical performances of the composites were discussed in terms of melting point, latent heat and thermal conductivity, which were characterized using Fourier transformed infrared (FTIR) spectroscopy, differential scanning calorimetry (DSC) and the transient hot wire (THW) method. The cost effectiveness of the composites was also considered from the point of view of two indexes, i.e., thermal conductivity per unit cost kc and heat capacity per unit cost Qc. The results revealed that the melting point of composites with EG continuously decreased with increasing mass ratio of additive due to the surface energy variation, while for the CNTs composites, it remained nearly constant. The latent heat of both composites gradually decreased as a function of mass ratio because of the replacement of erythritol by additives. The thermal conductivities of the composites also increased continuously with increasing addition of EG/CNTs. At the same mass ratio, EG appeared more effective than CNTs in enhancing the thermal conductivity, especially above 3wt%. The optimal proportion of EG for the erythritol-based composite, with respect to not only the variation of thermal conductivity but also the heat capacity and cost effectiveness, was approximately 4wt%.

To enhance the thermal conductivity of PCM for the M-TES system, erythritol-based composites were prepared using EG and CNTs as additives. Composites with different ratios of additives were compared by analyzing their differences in melting point, latent heat and thermal conductivity. In addition, two indexes, i.e., thermal conductivity per unit cost kc and heat capacity per unit cost Qc, were used to assess the economic feasibility of the composites. The conclusions of this study are as follows:

The melting point of EG composites continuously decreased with increasing additive, while that of CNTs composites remained nearly constant. The anomalous variations in the melting point could be attributed to the surface energy variation of erythritol, which was wrapped in the wormlike EG structure and could thus be regarded as many micro scale particles. The latent heat of composites gradually decreased with increasing addition of both EG and CNTs due to the replacement of erythritol with filler and the destruction of original lattices. The thermal conductivities of both composites increased continuously with increasing mass ratio of additive, though EG appeared more effective in enhancing the thermal conductivity than did CNTs for the erythritol-based PCM, especially when the mass ratio was above 3wt%.

The kc of EG composites increased as a function of mass ratio due to the significant enhancement of thermal conductivity and the additive’s low cost. However, the kc of the CNTs composites decreased because of the modest enhancement of thermal conductivity and high cost of CNTs. The higher the ratio of additives in the composites was, the lower the value of Qc became. Based on this comprehensive analysis of the thermal conductivity enhancement, heat capacity and economy of composites, the optimal ratio of EG was 4wt%. The results indicate the appropriate additive and ratio for the preparation of erythritol-based composites, which will ultimately contribute to the optimization of heat storage processes for M-TES.

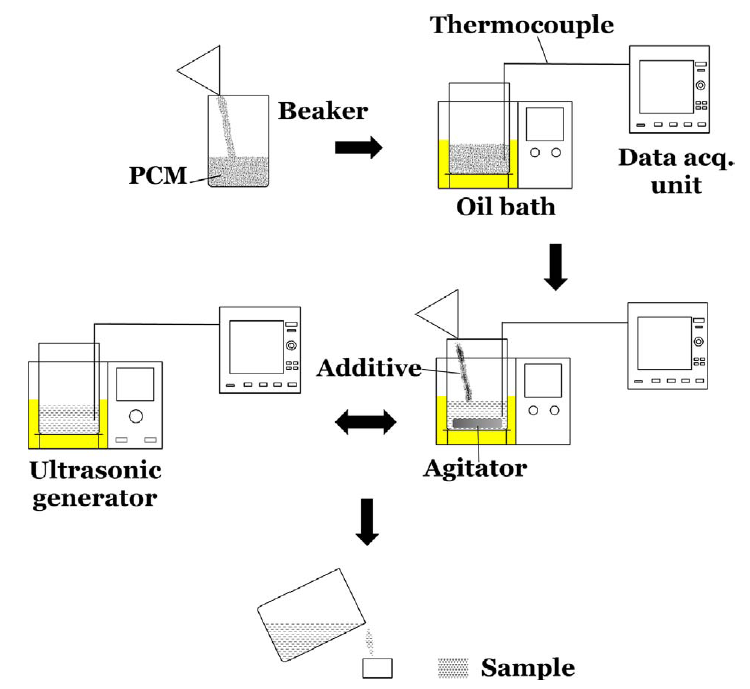

Fig.1. Procedure for composite preparation via melting dispersion