Phase change heat transfer is extensively used in chemical industry, refrigeration, solar power, and thermal management of opto-, electric-, and electronic-devices. For a long time, manufacturing of micro-structures and micro/nano composite structures is considered to be a very effective method for phase change heat transfer enhancement. The performances depend on the size and geometry of the micro/mini structures. However, for a specific geometric structure, the performance of the heat transfer system may become poor once the heat transfer conditions change due to the fluctuation of heat release. For instance, a structure with high heat transfer coefficient (HTC) for water can probably be not good for organic fluids because of the different thermo-physical properties of the fluids. Thus, there is a need to invent such kind of micro/mini structures for heat transfer that can adaptively change their geometries according to the heat transfer conditions.

Recently, IET researchers proposed a novel approach of improving the phase change heat transfer performance by using a heat transfer surface with adaptively deformable microstructures. The surface was invented in a collaborative study with Professor Hai-Chang Jiang in the Institute of Metal Research (IMR), Chinese Academy of Sciences (CAS). The macro-scale deformation was achieved by shape-memory alloys (SMAs). A SMA is a kind of alloy that “remembers” its original shape and that returns to its pre-deformed shape when heated. And the deformation is reversible for more than millions of times, which is obtained by the transformation from martensite to austenite at a certain temperature. Alloying constituents can be regulated to control the transformation temperatures of the SMA.

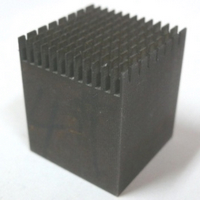

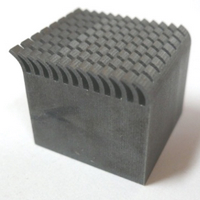

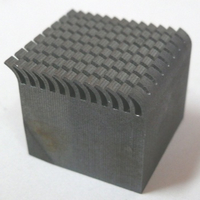

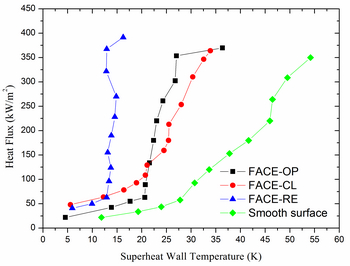

Three types of heat transfer enhancement structures were manufactured shown in Fig. 1. In all the three types, the serrate fins were made by two gouging processes crossing each other. Remarkably, for the bent fins of the third type (FACE-RE), it can return to the original straight geometry when the surface is heated to a temperature higher than the transformation point of 353 K. As shown in the Figs. 2, the recoverable surfaces made of SMA have advantages in heat transfer over the usual unrecoverable surfaces both for the improvement of HTC and the extending of operating range. In particular, the heat transfer over FACE-RE combines the merits of FACE-CL at low heat flux and FACE-OP at high heat flux. The enhancement heat transfer mechanism is shown in figure 3.

Besides the enhanced boiling surfaces, the IET researchers are promoting the application research of the deformable SMA structures in devise heat transfer devices, such as compact heat exchanges, heat pipes, and CPLs etc., where the structures can be used as a means of both heat transfer enhancement and control.

This work was funded by the Natural Science Foundation of China and the 1000-Young-Talent Project of China. The results have been reported on Applied Physics Letters (T. Wang, Y.Y. Jiang, H.C. Jiang, C. Guo, C.H. Guo, D.W. Tang, L.J. Rong, Surface with recoverable mini-structures made of shape-memory alloys for adaptive-control of boiling heat transfer, Appl. Phys. Letts., 107(2), 023904, DOI:10.103/1.4926987, 2015.)and in the Proceedings of ASME 2015 International Mechanical Engineering Congress & Exposition.

(a) open-tunnel surface (FACE-OP) (b) closed-tunnel surface (FACE-CL) (c) surface with recoverable fins (FACE-RE)

Fig. 1 Enhanced heat transfer structures made of SMA

Fig.2 Heat transfer performances of the three surfaces

(a)Bubbles nucleate inside tunnels (b)Bubble slugs and film meniscus form (c)Nucleation sites produce when tunnels open

Fig.3 Schematics of large amount of nucleate sites producing during the transformation of the recoverable structures (FACE-RE)