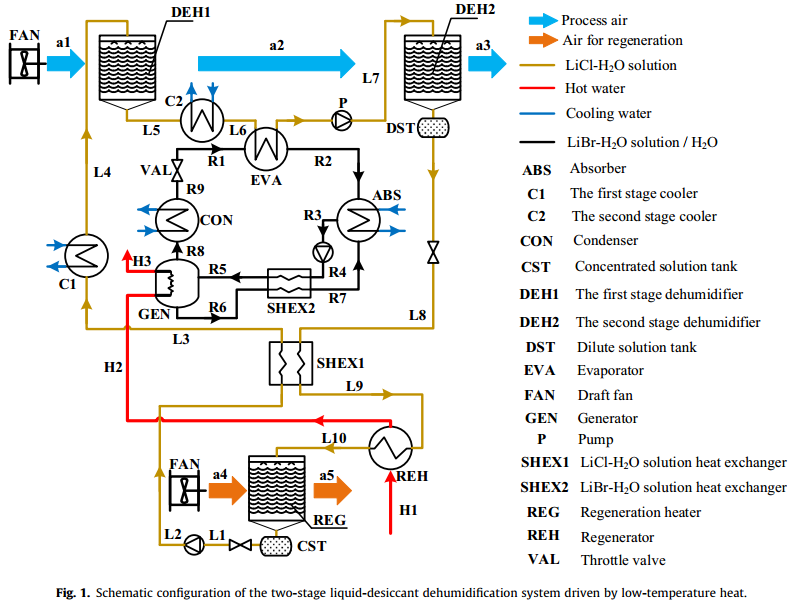

Cooling dehumidification driven by power is widely used in industrial processes to obtain dry air, but the main drawback is its large power consumption. In these processes, large amounts of low-temperature waste heat are released to the environment directly, so there is a great energy-saving potential to recover low-temperature waste heat and generate dry air. A new two-stage liquid desiccant dehumidification system with the cascade utilization of low-temperature heat is proposed. The waste heat is used in a cascade manner. The higher-temperature heat is used to generate a strong desiccant solution, which will be used in the first-stage dehumidifier. The lower-temperature heat is used to drive a single-effect absorption refrigerator and provide cooling energy to the second-stage dehumidifier. Simulation results showed that the proposed system can reduce electricity consumption by 92.29% compared with the conventional cooling dehumidification system driven by power. The ratio of electricity savings to absorbed heat can reach 7.35%. The advantage of the cascade utilization of the low-temperature heat was further illuminated by studying the driving force in the dehumidifiers, and a preliminary economic and environmental analysis was performed. The increased initial investment can be recovered in only 3.39 years.

Approximately 11,028 tons of standard coal is saved per year, and a reduction of 27,488 tons CO2 can also be realized per year. Finally, a parametric sensitivity analysis was conducted to optimize the system performance. This study may provide a new method to perform dehumidification by efficiently using a low-temperature heat source.

Conclusion:

A new two-stage liquid desiccant dehumidification system that is based on the cascaded utilization of low-temperature heat for industrial application is proposed. Waste heat, solar energy, or geothermal resources can be utilized as the heat source. The new system can be adopted as a stand-alone appliance to realize a high moisture load. The problem of carryover in the dehumidifier can be solved to some extent by applying a demister. The new system can save 3.59 MW power compared with the conventional cooling dehumidification system, and the power saving ratio (PSR) can reach 92.29%. More importantly, the equivalent power generation efficiency (ηeq) can reach 7.35%, which is 5.1 percentage points higher than that of an organic Rankine cycle using R245fa as its working fluid, as studied in a previous paper.

The advantage of the cascaded use of the low-temperature heat was elucidated by studying the driving force in the dehumidification process. Due to the cascaded utilization of the low-temperature heat, an improved moisture removal ability of the desiccant solution is achieved. Consequently, the average driving force difference in the new system can decrease by at least 22%. An exergy analysis of the dehumidification process should be conducted in the next step to further clarify the advantages of the cascade utilization of heat on the moisture absorption ability of the desiccant solution.

A parametric sensitivity analysis was performed to study the impact of the second-stage dehumidification temperature, strong LiCl aqueous solution mass concentration, and mass flow ratio between the desiccant solution and process air on the thermodynamic performance of the proposed system. The COPs have optimal values when values of 18.9℃, 0.38, and 0.97 are adopted for t7, y1 and a, respectively. A preliminarily economic and environmental analysis was conducted in this paper. In total, 27,572 MWh of electric power per year could be saved, and the corresponding cost savings are 2,197,704 US $/year. The increased initial investment can thus be recovered in only 3.39 years. The reduced power consumption equivalently leads to the reduction of CO2 emissions by 27,488 tons per year. If the benefit of the clean development mechanism (CDM) is also considered, the payback period would be reduced further. This study may provide a new efficient method to perform deep dehumidification for industrial applications by utilizing low-temperature heat.

The results have been published on Applied Energy 207 (2017) 643–653.