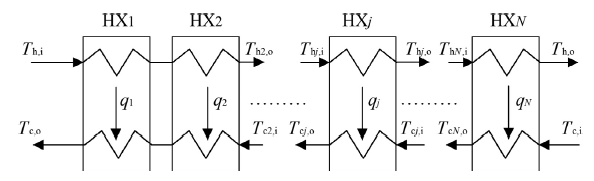

The segmental design method is employed to accurately capture the drastic variations of properties in the supercritical carbon dioxide (S-CO2) recuperator. The local heat capacity flow rates of both fluids have drastic changes in sub-heat exchangers even the mass flow rates of both fluids remain unchanged. When the heat duty is given, the local heat conductance, local temperature difference, local effectiveness and local entransy dissipation number have extremums, which appear in the vicinity of the heat capacity rate ratio is one. The heat transfer performance of recuperator improves at the expense of heat conductance. When the total heat conductance is fixed, there exist the maximum local heat flux rates, and the local effectiveness tends to be constant after the local heat capacity rate ratio reaches one, the local entransy dissipation number has the relatively coherent performance behavior in the sub-heat exchangers. The local heat capacity rate ratio has crucial influences on the heat transfer performance of recuperator, and the design parameters must be considered carefully in the design of S-CO2 recuperator.

Conclusions

The performance analysis of recuperator based on S-CO2 Brayton cycle is conducted in the present work. The segmental design method is employed due to the drastic variations of properties in the recuperator. When the design parameters of hot fluid are given, there exist extremums for local heat conductance, local logarithmic mean temperature difference, local effectiveness and local entransy dissipation number in the sub-heat exchangers along the flow direction of hot fluid. The maximums appear around the intersection point of heat capacity rates of both fluids. The total heat conductance increases as the mass flow rate of cold fluid increases, while the total entransy dissipation number decreases. The heat transfer performance of heat exchanger improves at the expense of heat conductance. When the total heat conductance is fixed, the local heat capacity rate ratio decreases generally along the flow direction of hot fluid but does not decrease monotonously as the mass flow rate of cold fluid decreases. The maximum value of local heat transfer rate appears in the neighborhood of local heat capacity rate ratio is one. When the heat capacity rate ratio is less than one, local effectiveness decreases along the flow direction of hot fluid; while the local effectiveness tends to be constant as the mass flow rate of cold fluid increases when the heat capacity rate ratio exceeds one.The local entransy dissipation number has almost monotonous changing tend in the sub-heat exchangers along the flow direction of hot fluid. The total heat duty decreases as the mass flow rate of cold fluid increases. The minimum total entransy dissipation number appears at P = 7.4 MPa and P = 8.0 MPa. The increasing inlet pressure of hot fluid deteriorates the heat transfer performance of recuperator. The sharp changes of properties have significant influences on the performance of recuperator, and the design parameters must be carefully considered in the design of S-CO2 recuperator to avoid temperature cross and improve its performance.

The results have been published on Applied Energy 164 (2016) 21–27.

The schematic diagram of sub-heat exchangers