Effects of injection pressure fluctuations on high-pressure and evaporating spray behaviour,especially under the representative modern diesel engine injection conditions,were carefully evaluated by using a well validated two-stage modelling approach.The numerical results in-dicate that as the injection pressure fluctuates more drastically both liquid and gas phase mo-tions in the spray field will be more intensively disturbed.Furthermore,the injection pressure fluctuations have strong potential to enhance fuel/gas mixing processes inside high-pressure and evaporating diesel spray field.

Conclusions

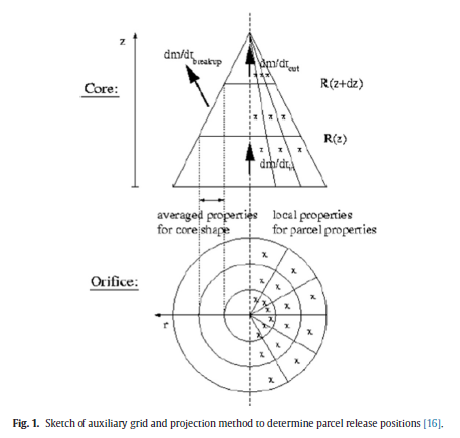

In the current study, effects of the pressure fluctuations with a typical frequency inside the injection nozzles on high-pressure and evaporating spray behaviour, especially under the representative diesel engine injection conditions, were evaluated by using a well validated two-stage modelling approach. The main conclusions can be summarized as follows: Firstly, the real injection pressure fluctuation can be regarded as one of major disturbance sources to the motions of both liquid phase and gas phase within the spray field, moreover, as injection pressure fluctuates more drastically it will disturb the spray field more intensively. For example, as the amplitude of injection pressure fluctuation with a representative frequency increases, much sharper variations in liquid phase penetration and more intense gas turbulence are induced simultaneously. Secondly, under the cases with sine-wave-type injection pressure fluctuations the corresponding liquid phase penetrations tend to show similar trends. However, for the case without injection pressure fluctuations the liquid phase penetration tends to be a constant and its value is smaller than those under the cases with injection pressure fluctuations. Thirdly, in contrast to the fuel/air equivalence ratio distribution for the case without injection pressure fluctuation, there is no dense core formed inside the fuel/air equivalence ratio distribution under the cases with injection pressure fluctuations. Furthermore, as the amplitude of injection pressure fluctuation with a representative frequency increases, the front area of fuel/air equivalence ratio distribution becomes wider and the whole distribution region tends to be closer to homogeneous. Therefore, strong injection pressure fluctuations have great potential to enhance fuel/gas mixing processes inside diesel spray field.

The results have been published on Applied Mathematical Modelling 40 (2016) 4032–4043.