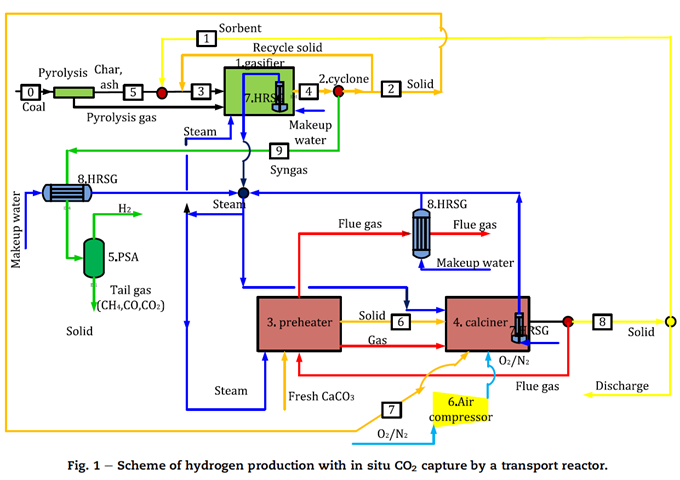

Calcium looping process (CLP) is one kind of carbonaceous material gasification process applied in the H2 rich syngas production and CO2 separation. In this research, a transport reactor with efficient heat and mass transfer and better gas and solid mixing was applied as the gasifier to produce H2 rich syngas with in situ CO2 capture. The primary objective of this research was to investigate the feasible operation conditions for gasifier and entire looping process. The gasification process was analyzed by model based on the reactor hydrodynamics and chemical kinetics. Influences of operating parameters, i.e. temperature, steam to carbon ratio and pressure, on the reactor hydrodynamics, reaction rates and conversion ratios, syngas flow and compositions, steam and power consumption were given and discussed. Feasible operation conditions for gasifier and system configuration were proposed according to the heat and power balance, H2 yield and systematic energy conversion efficiency. Simulation results indicated that feasible operation with H2 and power co-production can be achieved with the gasification temperature of 1273 K, pressure of 0.9 MPa, steam to carbon ratio of 1.8 and CaO to carbon ratio of 1.0. For this feasible operation, the H2 output exceeded 0.78 Nm3 per kg coal and energy conversion efficiency was higher than 40%.

Conclusion

The gasification and regeneration unit were modeled and investigated based on reactor hydrodynamics and chemical kinetics. Influences of gasification parameters, such as temperature, steam to carbon ratio and pressure, on units and system performance were investigated based on sensitive study. A coproduction system with gas turbine power generation fired by PSA tail gas and corresponding feasible operation conditions was proposed. The main conclusions were shown as follows.

1) The combination of gas turbine power generation fired by PSA tail gas with CLP can help to solve the problem of heat and power balance. With the improved system, feasible operation can be achieved. For example, at gasification temperature 800℃, pressure 0.9 MPa, SC/Ccoal =1.8 and CaO/Ccoal =1.0, H2 output can exceed 0.78 Nm3/kg coal and energy conversion efficiency higher than 40%. In this case, transport reactor can produce H2 rich syngas with H2 molar fraction 78% and LHV 13.25 MJ/Nm3, and 94.5% CO2 was captured by CaO.

2) Sensitive study showed that gasifier and system performance can be improved by adjusting gasification parameters. H2 yield can be increased with ST/Ccoal. Considering the increment and heat balance, the suitable SC/Ccoal range was from 1.5 to 2.0. H2 yield and mole fraction, heat and power balance were very sensitive to temperature. But at higher temperature, carbonation reaction ceased to happen, which lead to an increase of CO2 content. The suitable temperature range should not be higher than 803℃ under the conditions discussed in this research. More char and CaO can be converted with the increase of pressure. At gasification pressure 1.2 MPa, H2 yield can reach 1.1 Nm3 per kg coal. H2 mole fraction can be increased up to 80%. But at higher pressure, system steam and power balance were difficult to maintain. Furthermore, hydrodynamic problem will appear with pressure increase. More steam or N2 should be provided to regenerator for decreasing CO2 partial pressure.

3) There are considerable points for refining the model in future work. Because much of methane was produced in pyrolysis process, a better prediction of pyrolysis process was important to predict gasifier performance better. In this manuscript, pyrolysis product was predicted by a generalized model. In it, some parameters were preset which may deviate from real condition. These parameters should be adjusted according to experiments. Apart from the prediction improvement about coal pyrolysis, other aspects should be improved including the kinetics considering the interactive effect of gasification and carbonation with CaO and alkali metal existence, more sophisticated hydrodynamics, more rigorous examination of melting point. However, the model provided a basic tool to describe the general trends of the process and to identify the effects of key operating variables. Moreover, it was useful to identify the promising process design and optimize the operation conditions.

The results have been published on INTERNATIONAL JOURNAL OF HYDROGEN ENERGY 41 (2016) 12000-12018.