Oxy-fuel circulating fluidized bed combustion (CFBC) has an advantage of being operated with high oxygen concentration, making it a better choice for CO2 capture. In order to study the emission of nitrogen oxides and SO2 under O2/RFG (recycle flue gas) firing mode with an overall O2 concentration of 50%, oxy-fuel combustion experiments with Datong coal were carried out in a 0.1MWth oxy-fuel CFBC apparatus. The effects of different operating conditions on gaseous pollution emission, including gas staging combustion, oxygen staging combustion, and excess oxygen ratio were investigated. The experimental results show that a lower secondary flow ratio improves the sulfur capture efficiency, although the fuel N conversion increases slightly. Oxygen staging combustion, which means decreasing the oxygen concentration in the primary flow and increasing it in the secondary flow, is a new and safe method for oxy-fuel combustion with high oxygen concentration. A reasonably low excess oxygen ratio for the oxy-fuel CFBC operation is beneficial to simultaneously enable a decrease in the fuel N conversion and an improvement in the sulfur capture efficiency.

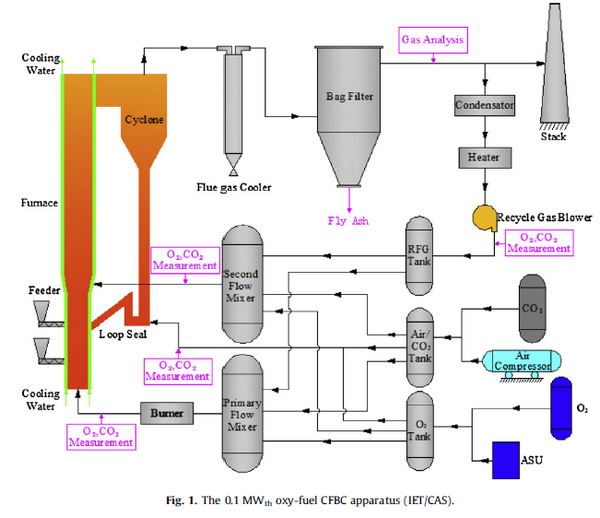

In order to investigate the emission of nitrogen oxides and SO2 in the O2/RFG firing mode with an overall O2 concentration of 50%, oxy-fuel combustion experiments with Datong coal were carried out in a 0.1 MWth oxy-fuel circulating fluidized bed combustion (CFBC) apparatus. The combustion temperature is about 850 ℃ and the velocity in the lower part of the combustor is in the range 3.3–4.9 m/s. The CO2 concentration in the flue gas ranges between 84.5% and 92.6%, and the tests are stable. The effects of different operating parameters, including the secondary flow ratios (29.2%, 41.2%, and 49.8%), oxygen concentration in the primary flow (32%, 38%, 43%, and 50%), and the excess oxygen ratio (1.06, 1.11, 1.16, and 1.22) are investigated. On the basis of the experimental results, the following conclusions were derived:

(1) A lower secondary flow ratio is beneficial to improve sulfur capture efficiency, although the fuel N conversion would increase slightly.

(2) Oxygen staging combustion is a new and safe mode for oxy-fuel combustion by decreasing the oxygen concentration in the primary flow. The fuel N conversion increases and the sulfur capture efficiency decreases as the oxygen concentration in the primary flow decreases, because the temperature in the dense phase zone decreases. Therefore, the heating surface arrangement for a uniform temperature profile along the combustor height is rather important for oxygen staging combustion.

(3) A reasonably low excess oxygen ratio for the oxy-fuel CFBC operation is beneficial to simultaneously enable a decrease in the fuel N conversion and an improvement in the sulfur capture efficiency.

The results have been published on FUEL Volume:146 Pages:81-87.