Research Fields

R&D of circulating fluidized bed (CFB) technology and foundational technology of engineering thermophysics, including high efficient clean combustion, pyrolysis and/or gasification conversion, comprehensive energy conservation and emission reduction, multi-phase flow and its diagnosis, combustion chemistry and catalytic combustion.

Research Focus:

1. Supercritical CFB technology: key technology and components, including air-solid two phase flow, furnace structure and thermal arrangements

2. CFB boiler technology for high efficiency and low emission, especially for ultra-low NOx emission combustion without SCR or SNCR.

3. CFB coal gasification technology: R&D and system integration of CFB coal gasification technology with atmosphere pressure for industrial fuel gas, R&D of pressurized CFB coal gasification for synthetical gas

4. R&D of CFB gradated conversion of low rank coal: coupling technology of pyrolysis and combustion in CFB for elevated utilization of coal

5. Fuel preheating combustion technology with high efficiency and low NOx emission

6. CFB oxy-fuel combustion at high oxygen concentration

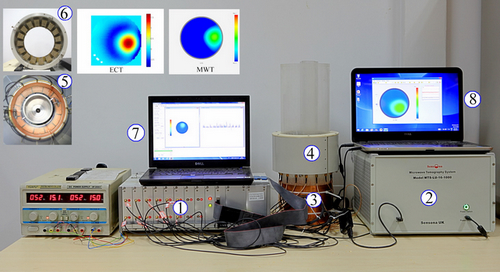

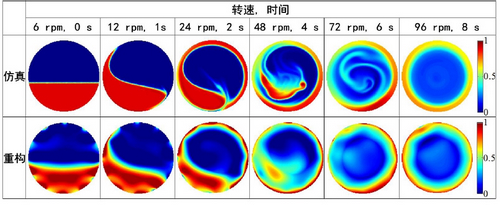

7. Numerical simulation and experimental measurement of multiphase flow: multi-scale numerical calculation of complex gas-solid flow, capacitance microwave tomography, and complex dielectric constant imaging algorithm

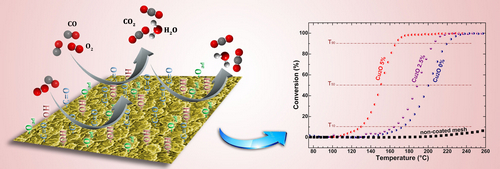

8. Combustion chemistry and combustion diagnosis technology: low-temperature oxidation and laminar premixed flame of multi alternative fuels, the synthesis of metal oxide catalysts, the effect of different catalysts on fuel low-temperatures combustion, and quantitative analysis of reaction process

Scientific Research Instruments and Equipment

Three sets of large scale cold test platforms were established, i.e. CFB cold test system with polygon furnace, coal burner cold test platform,and semi-coke transport cold test platform.

Two set of large scale hot test platforms were established, i.e. MW grade pilot plant on oxygen-fuel pressurized CFB, and 40t/h hot semi-coke transport pilot plant. 40t/d industrial pilot plant of combusting residue carbon from coal gasification in CFB and producing high-temperature steam was built.

There are several sets of experimental rigs for fundamental research, including chemical vapor deposition, catalytic combustion, low temperature oxidation, laminar premixed flame molecular-beam photoionization mass spectrometry, measurement and control system of complex fluidized bed reactor, and measurement and optimization of complex gas-solid fluidization processes.

Besides, there are several sets of advanced test and analysis instruments, including TG-MS-FTIR, Agilent GC 7890B, Agilent GC-MS 7890B-5977A, FTIR, TG, etc.

Major Projects

In 2015, there were 34 research projects in all, and half comes from the government and half from enterprises.

The key research projects include New CFB Technology for Energy Conservation and Environment Protection, which is a special project for international technology cooperation, Homogeneous and Heterogeneous Combustion and Their in-situ Spectrometric Investigation and Application which is thousand youth talents recruitment program, Measurement and Optimization of Complex Gas-solid Fluidization Processes which is a major international (regional) cooperation project of NSFC. In addition, seven research programs of NSFC are undertaken.

The key R&D projects from CAS include Semi-coke/coal Clean and High Efficient Combustion Technology and Demonstration which is the strategic priority research program, Gasification Pilot Plant on Oxygen-enriched Pressurized CFB with Multi-fuel which is a special program of renovation and purchase, Measuring and Control System of Complex Fluidized Bed Reactor which is a major scientific instrument development program, CFB Oxygen-enriched Combustion Technology which is an international cooperation program of bureau of international cooperation, and Numerical Calculation and Experimental measurement of Gas-solid Flow which is a preferred support project of hundred talents program.

Major Achievements of 2015

In the aspect of supercritical CFB technology development, the uniformity of bed material distribution among the three re-circulation loops and the gas-solid flow characteristics of 350MW CFB boiler with polygon furnace were optimized through cold experiments and numerical simulation, and the results reveal that the main deviation of bed material is less than 6%; The demonstration project of 350MW supercritical CFB boiler started to construct, and the basic scheme design of 660MW ultra-supercritical CFB boiler was finished.

The whole process oxy-fuel combustion CFB pilot plant with MW level and high oxygen concentration and flue gas recirculation was established and the oxygen concentration can reach 50% and CO2 concentration after being purified in flue gas is 97%, the concentration of SO2 and NOx is 0. The key technology suitable for CFB oxy-fuel combustion a thigh oxygen concentration was developed, including the flue gas re-circulation system, gas supplying system, and temperature control in furnace.

Through the experiments conducted in semi-coke preheating combustion cold test platforms and hot test rigs, the basic method adjusting combustion temperature was obtained, and clean and high efficient combustion for pulverized semi-coke was realized with the combustion efficiency of 98.5% and NOx original production of less than 100 mg/m3 (@ 6% O2). 5MW pulverized coal burner was developed, and the design principle of pulverized semi-coke preheating combustion system was initially set up and put into use of demonstration project.

40t/d industrial pilot plant of combusting residue carbon from coal gasification in CFB and producing high-temperature steam was established. R&D of 100t/d boiler burning residue carbon was finished, and the design of demonstration project was also finished and the construction work has already begun.

The coupling technological process of pyrolysis and combustion in CFB was partially got through, and 100,000t/y CFB coal pyrolysis devices were successfully operated with full load for the first time in China.

CFB coal gasification technology with atmospheric pressure for industrial gas with the capacity of 25,000Nm3/h and 40,000Nm3/h were awarded the scientific and technological achievements identification by t he China Electrical Engineering Society and China Petroleum and Chemical Industry Association respectively, with the appraisal of reaching international advanced level. Gasification pilot plant on oxygen-enriched pressurized CFB with multi-fuel was established and a series of experiments were conducted with the fuel of coal and biomass, etc.

In the aspect of numerical calculation and experimental measurement of multiphase flow, full scale computational particle fluid dynamics (CPFD) simulation of complex gas-solid flow was conducted as well as coupling capacitance and electrostatic field simulation. Several research achievements have been demonstrated or applied in the enterprises.

In the aspect of combustion chemistry and catalytic ccombustion, the synthesis of chromium, copper and cobalt based catalysts and their catalytic combustion characteristics were studied, which improved the experimental database and chemical kinetics model base for low temperature oxidation of 1,3,5-trimethylbenzene, 1,2,4-trimethylbenzene and surrogate fuels (n-decane doped 1,3,5-trimethylbenzene).

In the aspect of quantitative analysis of reaction process, the quantitative analysis method based on mass spectrum was established, and proximate analysis based on equivalent characteristic spectrum analysis(ECSA) was developed and applied in many fields.

Organization and Personnel

There are 73 researchers, including 8 professors (one "Hundred Talents Program" and one "Thousand Youth Talents Program"), 12 associate professors/senior engineers, 28 graduate students and 3 post-doctor fellows (one foreign post-doctor fellow).

The scientific researchers serve as the expert of domestic-developed supercritical 600MW CFB boiler program of NDRC, and National 863 program in the subject of advanced clean coal energy, technical committee member of biomass power generation equipment standardization in the energy industry of China, editorial board member of journals of Combustion Science and Technology, Engineering Thermophysics, and Process Engineering, session chairs of the international conferences, such as 2015 Asia-Pacific Conference on Combustion, 2015 Annual Combustion Meeting of Engineering Thermophysics.

Patents and Paper

In 2015, 61 papers were published, among which 31 was indexed by SCI, and 41 by EI. 13 patents were applied and 13 invention patents were authorized.

In Chemical Engineering Journal (IF = 4.321), Catalytic complete oxidation of acetylene and propene over clay versus cordierite honeycomb monoliths without and with chemical vapor deposited cobalt oxide was published; in Faraday Discussions (IF = 4.194), In situ characterization of Cu-Co oxides for catalytic application was published; in RSC Advances(IF = 3.84), CVD synthesis of Cu2O films for catalytic application and Ailored synthesis of CoOx thin films for catalytic application were published; in Proceedings of the Combustion Institut (IF =2.262), Low-temperature deep oxidation of olefins and DME over cobalt ferrite was published.

Awards

One student was awarded the prize of ZhuLiyuehua Excellent Doctoral Dissertation, and 1 student was awarded the prize of Chen Xuejun Excellent Paper in the2015 Annual Multi-phase Meeting of Engineering Thermophysics.

International Cooperation and Exchanges

There is long-term communication and cooperation relationship between the laboratory and the research institutions and universities abroad. The research fellows attended the top-level conferences at home and abroad, including the 22nd FBC Conference, 6th Asian Particle Technology Symposium in which Prof. Wang Haigang gave an invited speech, 7th European Combustion Meeting, European CVD 20, AFRC 2015, ISMTMF 2015, and IEEE IST 2015 etc., and visited Great Britain, Japan, Hungary and Switzerland for experimental cooperation and academic communication.

Several foreign famous scholars were invited to visit the laboratory and gave lectures, including Prof. Peter Glarborg from Technical University of Denmark, Prof. Kaoru Maruta from Tohoku University, etc.

There is one doctor jointly trained with Manchester University in UK, and one with Canmet ENERGY Ottawa in Canada, and one post-doctor from Cameroon.

Dean: LYU Qinggang Tel: 86-10-82543053 E-mail: qglu@iet.cn

Deputy dean: NA Yongjie Tel: 86-10-82543058 E-mail: nayongjie@iet.cn

LI Shiyuan Tel: 86-10-82543055 E-mail: lishiyuan@iet.cn

40t/d industrial pilotplant of combusting residue carbon from coal gasification in CFB and producinghigh-temperature steam

catalyticcombustionplatform

capacitance and microwave measurement system

coupling of fluid field and electrostatic field for electrical capacitance tomography

application of copper oxide catalyzation

Kohse (Chairman of International Symposium on Combustion ) visiting IET

60000Nm3/h CFB coal gasifier with atmospheric pressure for industrial gas in Qian’anHebei Province

Kohse (Chairman of International Symposium on Combustion ) visiting IET

Professor Raffaella from Heriot-Watt University visiting IET

Download the attachment

Download the attachment

Laboratory