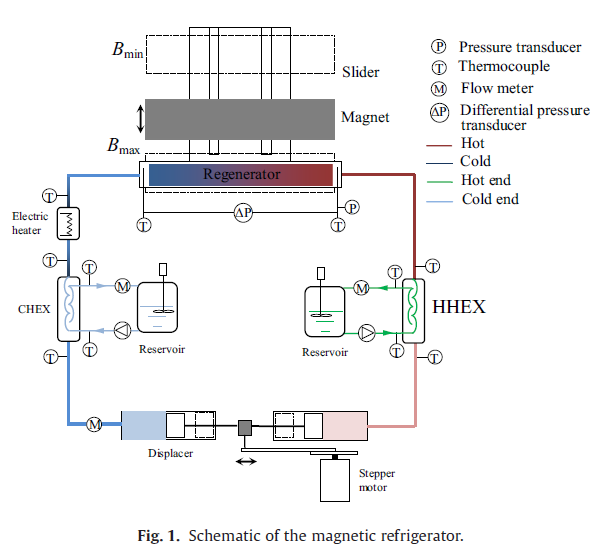

The paper reports numerical investigation of room temperature, active magnetocaloric regeneration (AMR)refrigerators/heat pumps using microchannel regenerator. The microchannel regenerators are made of a magnetocaloric material (MCM), Gd, with diameter of the circular channels ranging from 0.7 mm to 2.0 mm. Water, the working fluid, oscillates in the regenerator loop driven by two piston-cylinder displacers operating in a range of mass flow rates. Three dimensional conjugated fluid convection and conduction heat transfer in the microchannel regenerator was modeled and numerically simulated using ANSYS Fluent. The magnetocaloric effect (MCE) was incorporated into conservation of energy using a discrete method to simulate the magnetization and demagnetization of the MCM. The hot and cold end heat exchangers were treated with the ε–NTU method. Effects of utilization and porosity of the microchannel regenerator and cycle frequency on the cooling capacity and temperature span were examined. When the utilization, porosity and cycle frequency are 0.2, 0.5 and 5.0 Hz, respectively, the predicted maximum cooling capacity was about 22W for a 0.8T variation in intensity of magnetic field. The effects of magnetic field intensity, reservoir temperature span and flow rate profile on the refrigeration performance were also investigated. The performance of the microchannel regenerator is compared with that of the parallel plate regenerator for the no-load temperature span, cooling capacity and pumping power. Under specific geometric and operating conditions, the microchannel regenerator shows better performance than the parallel-plate one.

Conclusions

A hybrid numerical simulation for the room temperature magnetic refrigerator has been performed using Fluent. The three dimensional model for the microchannel regenerator is solved using finite-volume method and ε-NTU method is used for two heat exchangers. The numerical results show that the cooling capacity of the magnetic refrigerator is sensitive to the utilization, porosity, cycle frequency and flow rate profile. At a magnetic field change of 0.8T, when the maximum predicted cooling capacity is about 22 Wat the corresponding utilization, porosity and cycle frequency are 0.2, 0.5 and 5.0 Hz, respectively. The maximum no-load temperature span, however, is about ~23K at a utilization of 0.1 and frequency of 2.0 Hz. The cooling capacity increases linearly with the increase of the cycle frequency in the range studied and decreases linearly with the increase of the temperature difference between two reservoirs, and the more the change of magnetic field intensity is, the more the cooling capacity. Microchannel regenerator shows higher cooling capacity than parallel-plate regenerator by a maximum of ~7%.

The results have been published on Applied Thermal Engineering 102 (2016) 1126–1140.