An experimental study on a vertical shell-and-tube latent heat thermal storage unit with erythritol as storage media and air as heat transfer fluid (HTF) is conducted to evaluate the thermal behavior and heat transfer performance of the unit. The thermophysical properties of erythritol, such as melting temperature, melting enthalpy, thermal conductivity, and viscosity, are obtained. During charging, the molten phase change material (PCM) first occupies the top region and then spreads from top to bottom. During discharging, the PCM initially solidifies from the bottom region, and then the solid–liquid interface progresses uniformly from the inner tube to the outer shell, where natural convection plays a dominant role in the heat transfer at the liquid region. Moreover, increasing the inlet temperature and the mass flow rate of the HTF during charging obviously enhances the heat transfer in the PCM and shortens the charging time. Increasing the pressure of the HTF with the same mass flow rate shows little effect on the heat transfer in the PCM. In addition, increasing the mass flow rate of the HTF helps enhance heat transfer during discharging.

Conclusions

In this study, we investigated the melting and solidification behavior of erythritol in a shell-and-tube LHTS unit during charging and discharging. The HTF flows downwards during both charging and discharging. The phase change heat transfer characteristics of erythritol inside the annular space were thoroughly studied. The effects of operation parameters, such as mass flow rate, inlet temperature, and inlet air pressure of the HTF on the heat transfer, were studied. The following conclusions were drawn:

(1) Erythritol melts at 120.39℃ with the latent heat of 319.5 kJ/kg. The thermal conductivity of erythritol at solid state decreases linearly from 0.76 W/(mK) to 0.68 W/(mK) as temperature increases from 15℃ to 60℃; conversely, the thermal conductivity at liquid state increases as temperature increases. The viscosity of liquid erythritol decreases from 0.030 to 0.010 Pa s as the temperature increases from 120℃ to 170℃.

(2) As the melting process progresses, the molten PCM first occupies the top region and then spreads from top to bottom. Moreover, the effect of natural convection is enhanced as the molten PCM region and the temperature of the molten PCM increase. Natural convection plays an important role during melting.

(3) During solidification, the PCM starts to solidify from the bottom region at the beginning, and then the solid–liquid interface uniformly progresses from the inner tube to the outer shell. These results indicate the initial dominance of the natural convection before conduction replaces it.

(4) Increasing the inlet temperature and the mass flow rate of the HTF during charging can obviously enhance the heat transfer in the PCM, and increasing the HTF pressure with the same mass flow rate shows little effect on the heat transfer in the PCM. Increasing the mass flow rate of the HTF during discharging can enhance the heat transfer in the PCM.

The results have been published on International Journal of Heat and Mass Transfer 99 (2016) 770–781.

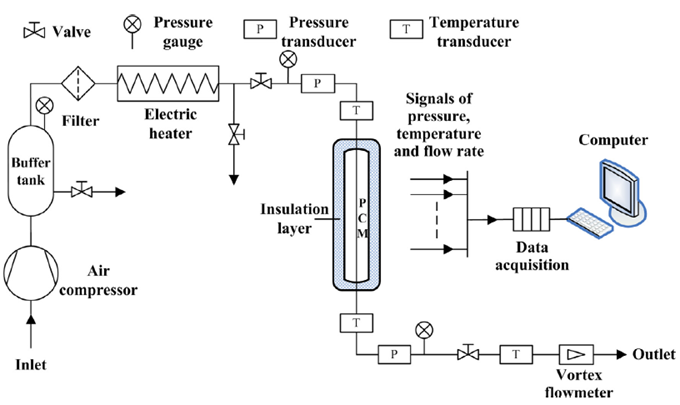

Schematic diagram of the experiment apparatus