Slagging behaviors of high alkali Zhundong coal during circulating fluidized bed (CFB) gasification were investigated in a 0.4 t/d CFB test rig for 72 h, with air-cooled ash deposition probes located along the gas flow direction. The microstructure, chemical compositions and mineral crystalline phases of ash were analyzed. Corrosion-reduced slagging and layered slagging were found on the ash deposition probes and the circulating air pipe, respectively. At the initial stage of corrosion-reduced slagging, Fe in the metal surface was transferred to an unsteady state by the corrosion of NaCl. Once corrosion occurred, the corrosion-reduced slagging was accelerated by the presence of sodium iron oxides and alkali sulfates. This type of slagging was greatly influenced by wall temperature, as it was more inclined to occur on the probes only at wall temperature above 495 ℃. The high density of circulating ash, which was rich in Ca, Na, Fe, S, Si and Mg in the form of low-melting-temperature sulfates and silicates, resulted in slagging on the circulating air pipe. A layered structure was observed on the cross-section of the slags, and its characteristics were determined by the distributions of Ca, S, Na and Fe. With the growth of the slags, the air hole in the circulating air pipe was blocked due to the aggregation of stickier fusant, which might cause unscheduled outages.

Conclusions

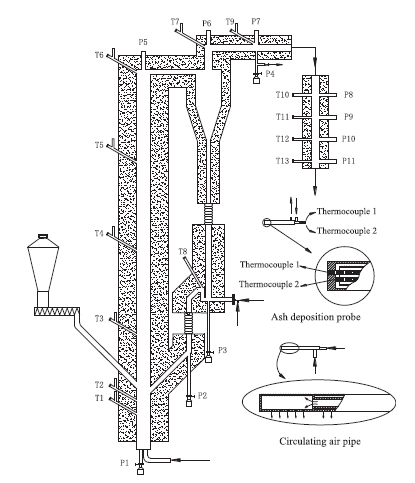

A 72-h gasification test with high alkali metal Zhundong coal was performed in a 0.4 t/d CFB test rig. The slags and deposits were characterized by SEM-EDS, XRD and XRF. The main conclusions are listed below.

(1) Corrosion-reduced slagging occurred on the ash deposition probes. At the initial stage of slagging, Fe on the metal surfaces was transferred to an unsteady state by the NaCl corrosion. Once corrosion occurred, the corrosion-reduced slagging was accelerated by the presence of sodium iron oxides and alkali sulfates. This type of slagging was greatly influenced by wall temperature, and it was more inclined to occur on the probes at wall temperature above 495 C in this study.

(2) The enrichment of Ca, Na, Fe, S, Si and Mg in the form of low-melting-temperature sulfates and silicates plays an important role in slagging on the circulating air pipe. The high density circulating ash in the loop seal facilitates the enrichment of mineral elements.

(3) A layered structure was observed on the cross-section of the slags on the circulating air pipe, and its characteristics were determined by the distributions of Ca, S, Na and Fe. With the slag growth, the air hole in the circulating air pipe was blocked by the aggregation of stickier fusant, causing unscheduled outages without taking effective measures.

The results have been published on Fuel 186 (2016) 140–149.

Fig. 1. Schematic diagram of 0.4 t/d CFB test system.