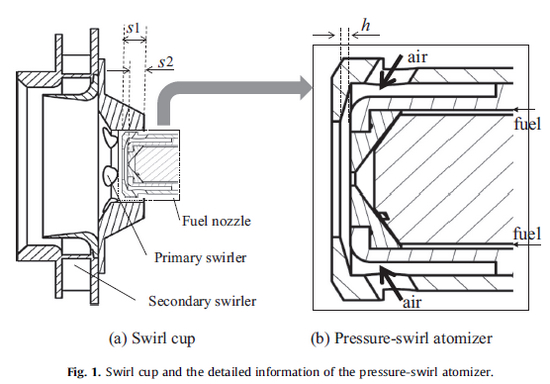

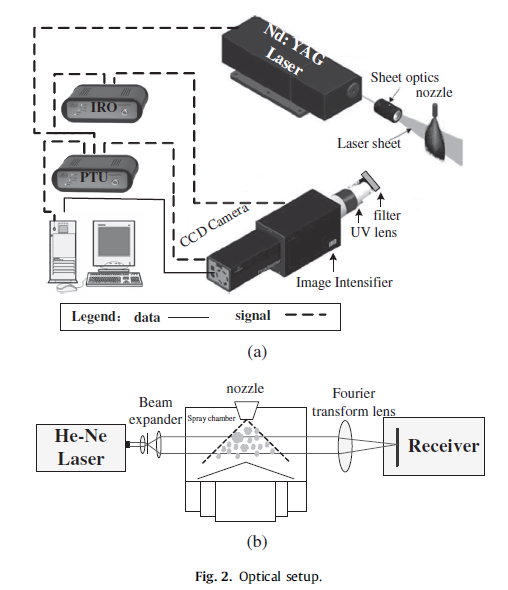

An experimental study on both spray and combustion were carried out in order to investigate the effects of gap of nozzle shroud on combustion stability and correlate the spray characteristics with some of combustion performances in a swirl-cup combustor, such as flame pattern, ignition and lean blow-out performances. The performances of ignition and lean blow-out were evaluated in a three-sector combustor in which only the middle dome is operated. Spray analyses were conducted on test sets in a quiescent open-air environment, with measurements of spray pattern by kerosene planar laser induced fluorescence (Kerosene-PLIF) and droplet size by Fraunhofer diffraction techniques. The optimum gap of nozzle shroud for ignition performance is obtained. Based on the droplets spatial distribution in the combustor with recognition of multi-phase nature of the ignition process, the phenomenon that the gap of nozzle shroud has a great impact on the ignition performance was analyzed. Meanwhile, one also analyzed the lean blowout performance associated with the droplets spatial distribution. By tuning the fuel mixture from ignition condition to the near lean blow-out condition, one found that the lean blow-out performance is less sensitive to the gap of nozzle shroud. Furthermore, CFD simulation results of the flow field under the typical combustor operation conditions were presented and discussed to provide insight into the interaction between air streams from anti-carbon apertures and primary swirler.

The effects of spray characteristics on the flame pattern and combustion stability of a swirl-cup combustor are carried out, focusing on effects of gap of fuel nozzle on ignition and LBO performances. The ignition performance is greatly improved with fuel/air ratio at ignition limit lower by 18%. Meanwhile, the chaotic flame and attachment of flame on front-end and liners of combustor are avoided by adjusting the gap of nozzle shroud. The combustion phenomena in ignition and LBO processes can be explained by the spray characteristics. The direct and close relationships between spray pattern and the flame pattern, combustion stability at ignition and near LBO conditions are obtained. Additionally, CFD analysis of flow field is conducted to understand the interactions between swirling air streams from primary swirler and jetting air streams from the purge holes. The relationships provide guidelines for the design of swirl-stabilized combustors, especially what spray characteristics benefit to ignition and flame stabilization. This work will make the prefilming atomization technology better incorporated into future aero-engine and provide great insight in the methodology of combustor design.

The results have been published on FUEL Volume:139 Pages:529-536.